Technische Beratung

Die technische Beratung steht Ihnen zur Ausarbeitung einer Lösung mit unserer Erfahrung zu Materialien, Fertigungstechnik und Anwendungen zur Verfügung. Hierbei steht die optimale und wirtschaftliche Umsetzung Ihrer Kundenanforderungen im Vordergrund.

- Materialauswahl nach wirtschaftlichen, technischen und zulassungsrelevanten Anforderungen.

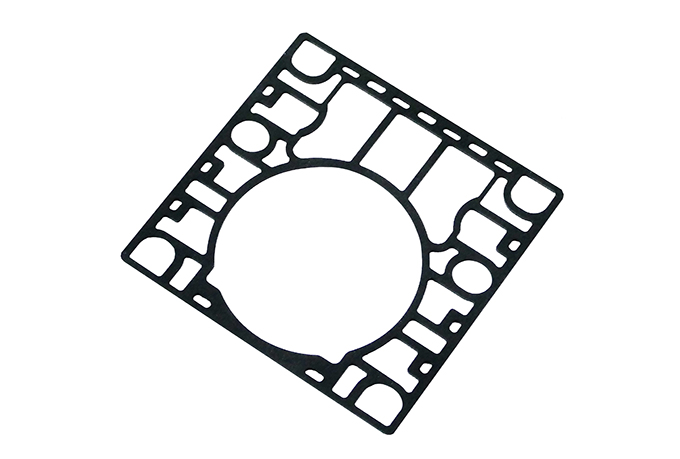

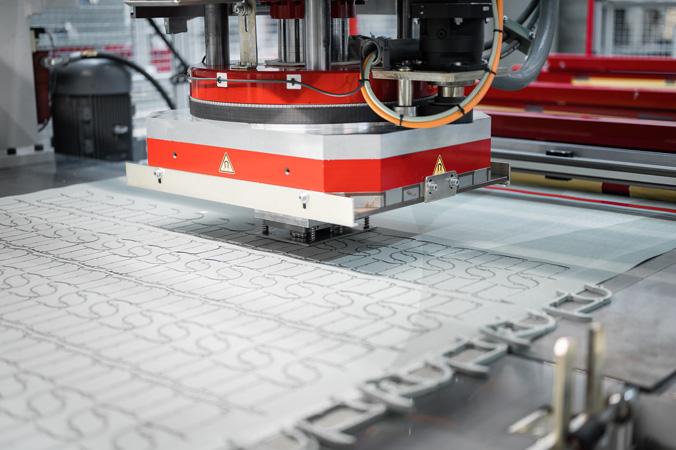

- Unterstützung bei der Auslegung der Bauteile mit unserem Know-How der Fertigungstechnik

- Berücksichtigung wirtschaftlicher Gesichtspunkte – Auswahl der geeigneten Herstellungstechnologie passend zum angefragten Artikelbedarf

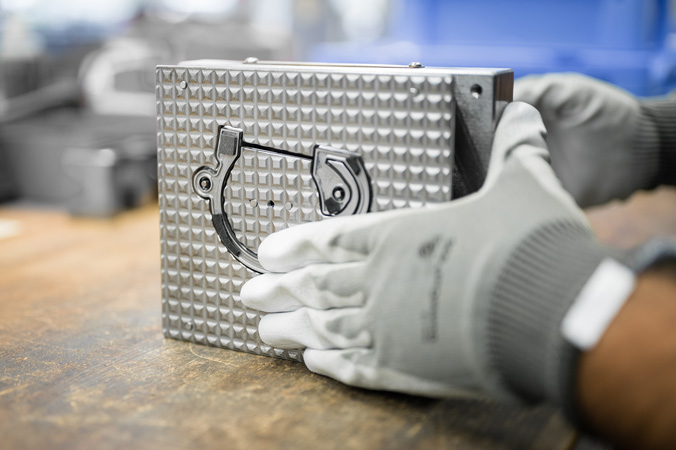

- Prüfung herstellbarer Toleranzen und besonderer Merkmale zur Erreichung bestmöglicher Qualität

- Empfehlungen zur Planung der Handhabung von Bauteilen im Warenfluss und der Montage des Kunden